On-line titration

- Continuous analysis of important process parameters

- Permanent determination of product characteristics

- Process optimization

- Saving raw and auxiliary materials

- Release of laboratory personnel

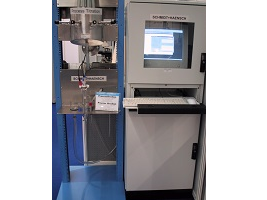

On-line titration system

A fast and accurate analysis of important process parameters is decisive to guarantee optimal process performance. The on-line process analysis enables continuous process control in order to be able to react fast to control or regulate the process in contrast to the time shifted and complicated laboratory determinations.

The automatic value determination results in a higher analysis frequency and offers the following advantages:

- Actual information about the process control

- Fast and opportune perception of disturbances

- Determination of product characteristics without interruption as part of the quality control

- Determination of characteristics of process streams in order to avoid product losses or to control limit levels

- Optimisation of process performance

- Combination of on-line analysis and automatic control systems

- Saving raw and auxiliary materials by more effective quality control and better compliance with process and product specificationsLower pollution by reducing hazardous substances

- Higher security by measurement in dangerous environment without contact with the measured substances

- Release of laboratory personnel from routine analysis so that they can handle more demanding and qualified tasks

Principle

(Part) streams of the product to be analysed are conducted to a sample selection system. The selected sample flows to the measuring module. Individual systems for sample preparation can be integrated or adapted prior to this.

In the process titration module, the sample volume is measured in a defined way in the reactor. Hot samples are cooled down in the double-jacketed reactor. Then the titration starts, resp. conductivity measurement etc.

The complete system is controlled by a personal computer with specially designed software for the application. After concluding the titration and calculation of results, these are transmitted via analogue and/or digital interfaces for record and process control purposes.

The modular system can also integrate several of SCHMIDT + HAENSCH’s instruments and some of other manufacturers. The modular concept and individual software modules allow us to offer flexible, customer tailored solutions. Herewith, the system can analyse samples from the raw materials to the quality control of the end product.

System Construction

- Robust construction, cabinet protection for PC and instruments: IP 55

- Customer tailored, modular design

- High process security and availability

- Flexible complement with data inputs, outputs and serial interfaces

Operation

- Simple operation on site

- Simple adaptation of analysis parameter

- Automatic cleaning

Processing of Results

- Flexible processing of measuring values

- Storage of measuring values

Maintenance/Service

- Easy maintenance due to simple construction and easy accessibility

- Remote control and maintenance of the process analyser via modem or net with an optional software module

Applications

Titrations, resp. incl. conductivity measurement in the sugar industry, chemical industry, etc.